Intelligent Weld Seam Inspection for industries

FOR QUALITY AND SAFETY

The requirements for quality and safety are increasing. Customers are increasingly demanding higher quality products at a lower price. A company can only remain one step ahead of the competition if it delivers consistent, excellent quality, sustainably reduces rework, and optimizes processes.

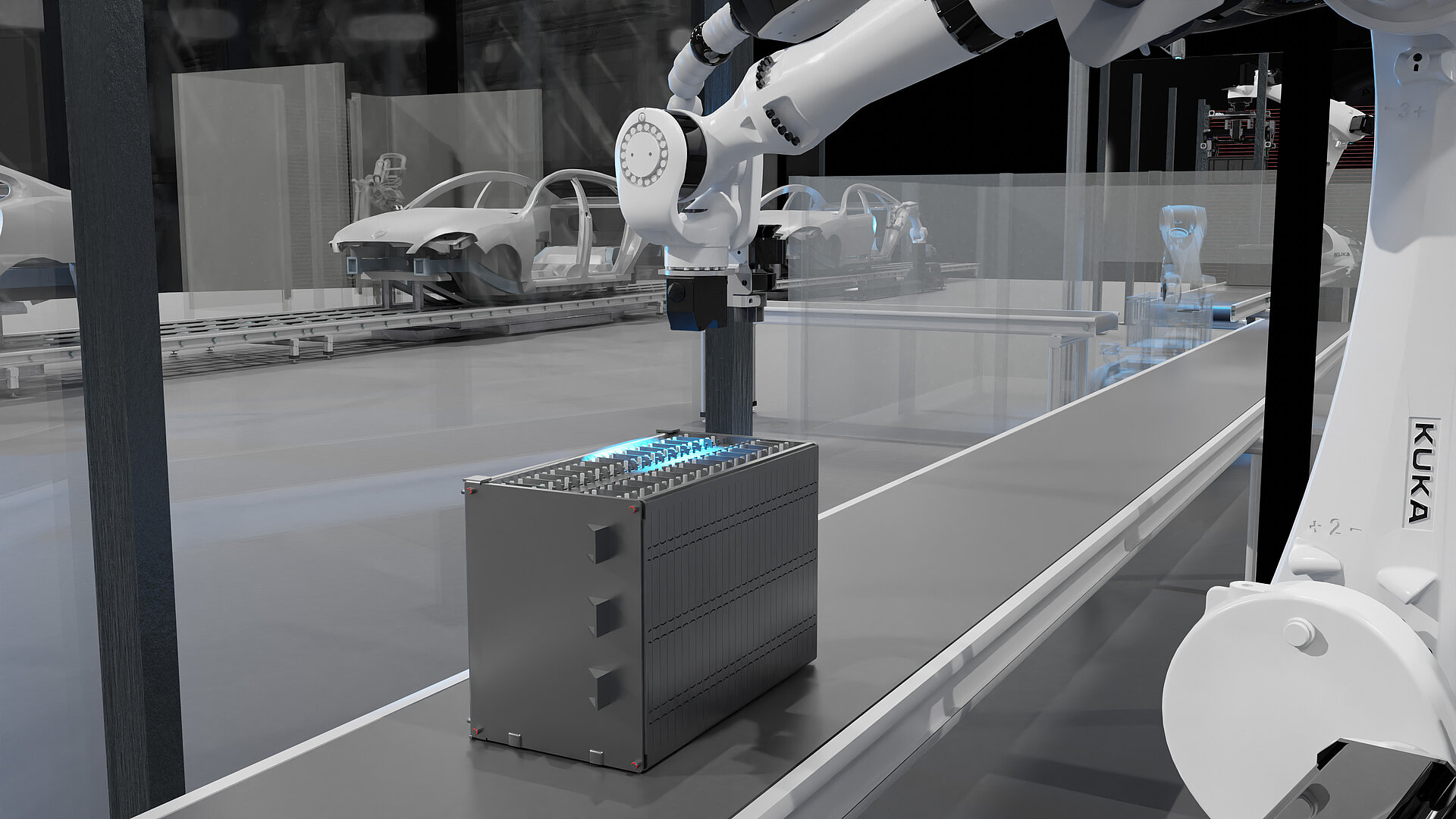

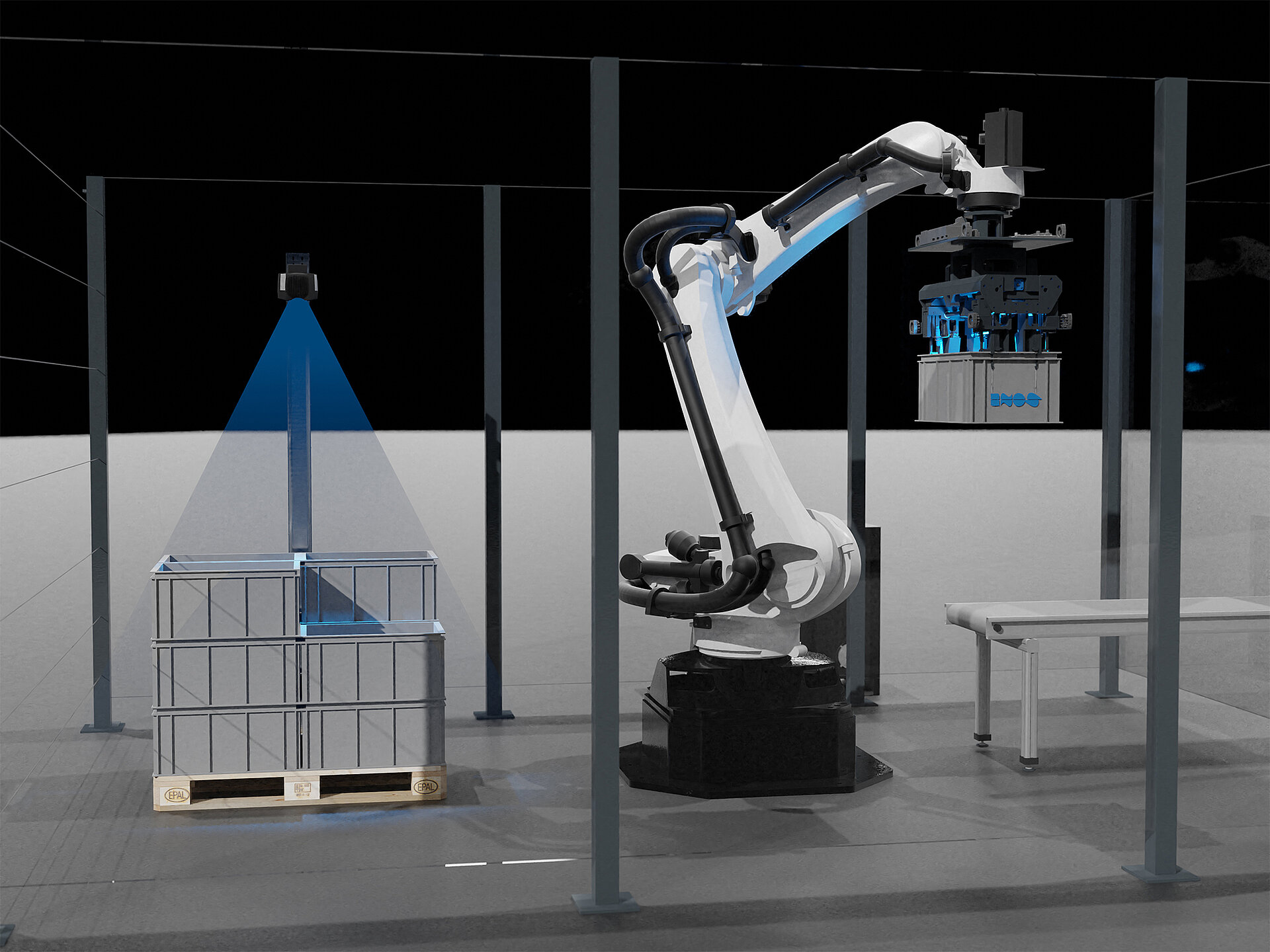

The automated Weld Seam Inspection from inos Automation will support you in mastering this challenge. The technology is designed to meet the highest quality standards. To achieve this, 3D weld seam inspection relies on various mechanisms and AI-supported approaches. Sensors detect production errors such as splashes, pores, or edge offsets in real-time. The weld seams are inspected in a non-destructive manner. This can be done during system operation or outside the line if required.

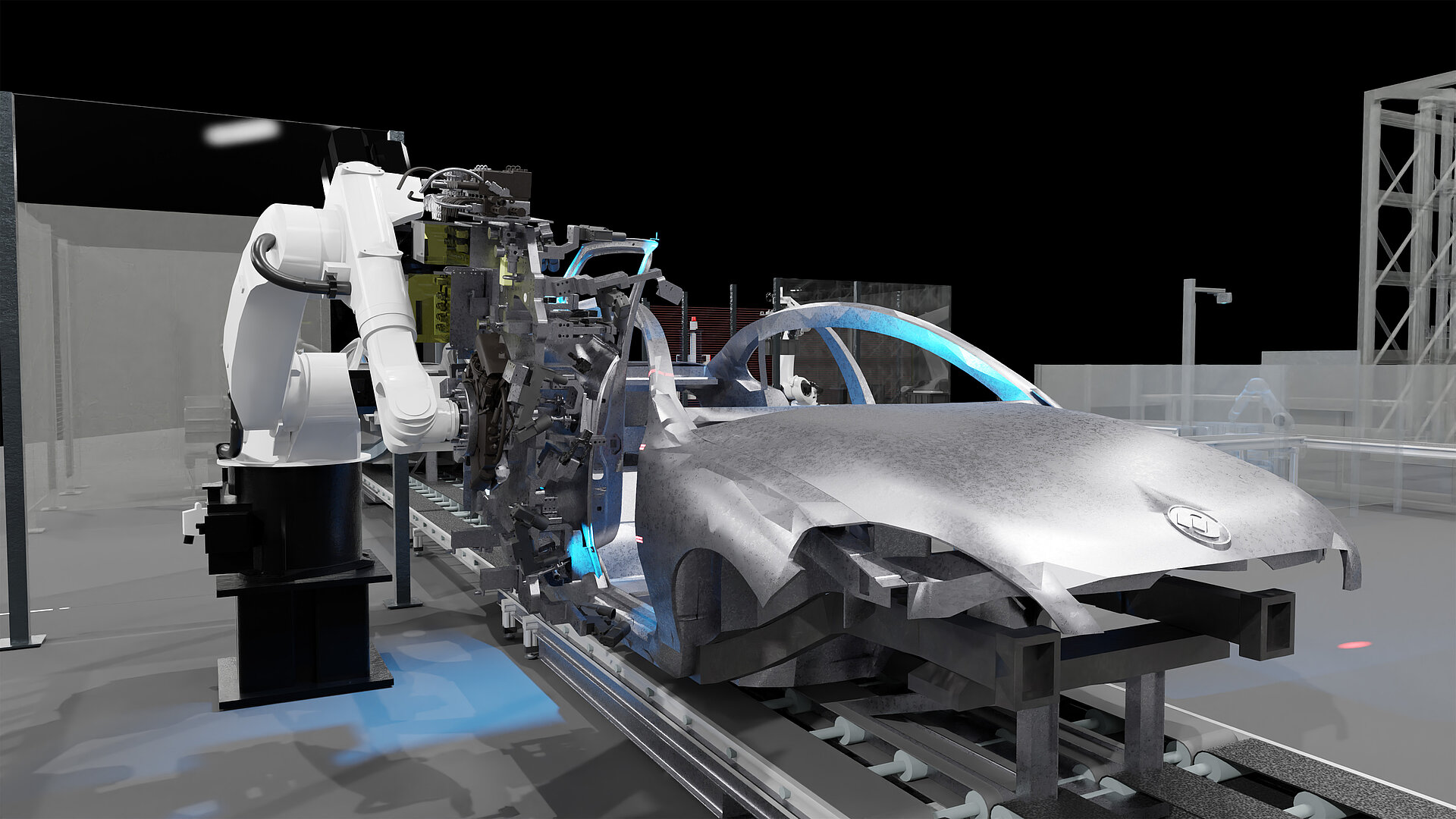

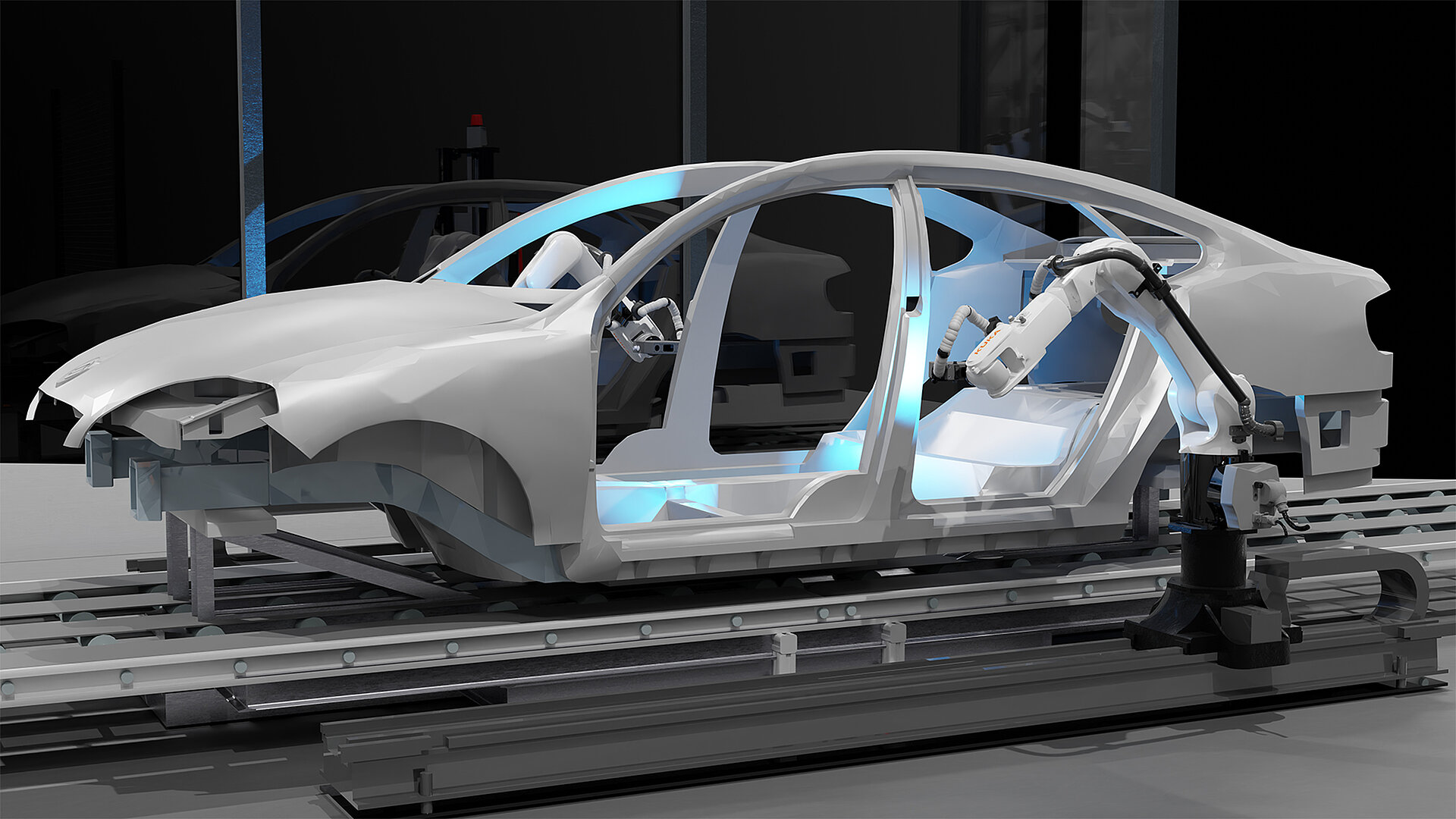

Weld Seam Inspection for automotives

Regarding product quality, OEMs are the pioneers – with inos Automation you stay ahead. inos Automation's precise, optical 3D Weld Seam Inspection detects any irregularities in your weld seams so that you can react immediately. This increases the safety of your end consumers on the one hand and strengthens your brand’s reputation on the other. inos Automation has been a high-performance partner to the automotive industry for over 25 years.

“inos Automation consistently develops processes and builds on many years of experience in automation and sensor technology. Our state-of-the-art analysis processes are based on AI algorithms. Our customers thus receive a prompt, verified assessment of the product's quality status and can initiate efficient corrective and improvement measures. ”

FAQ

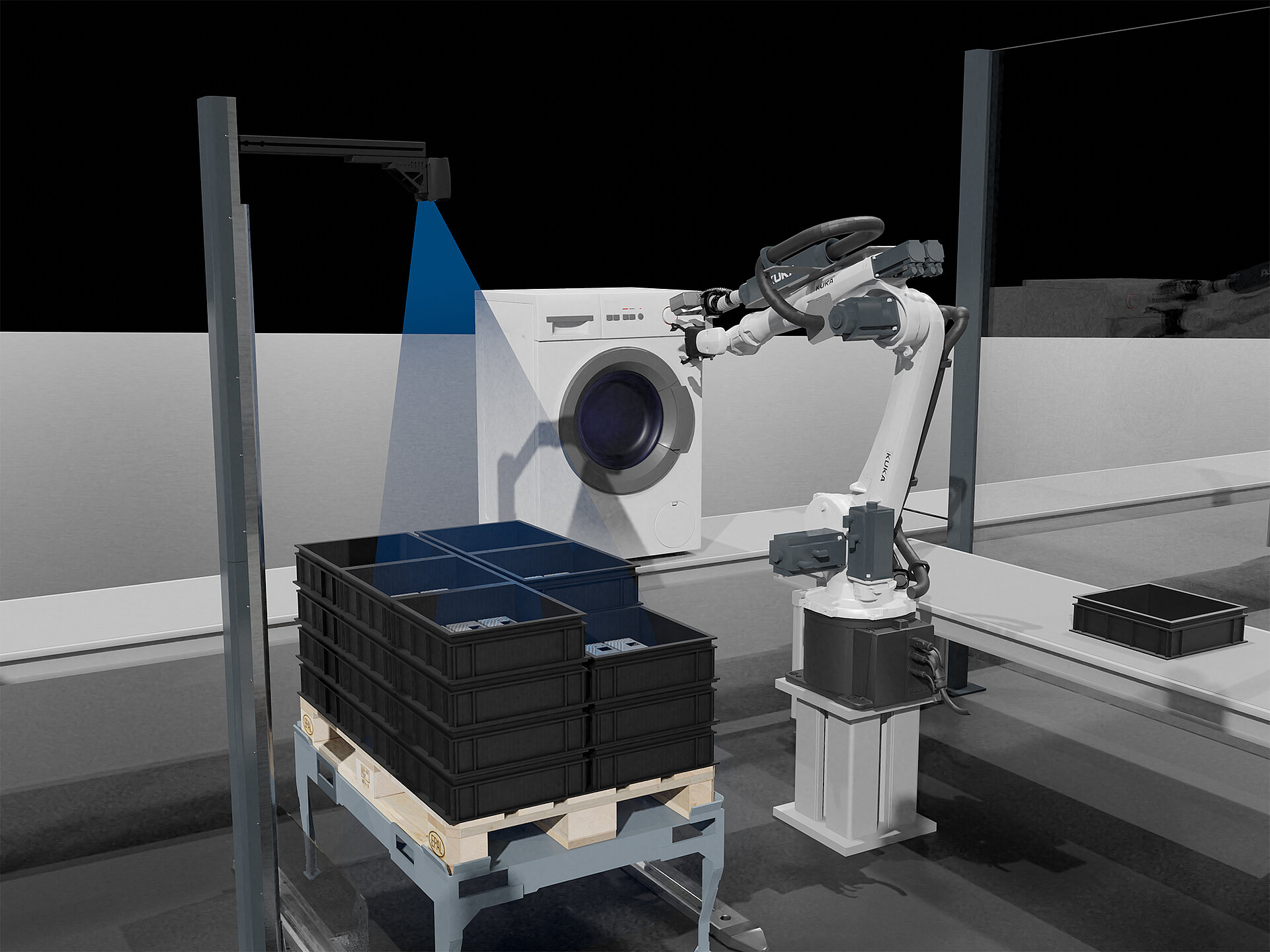

How does the Weld Seam Inspection work?

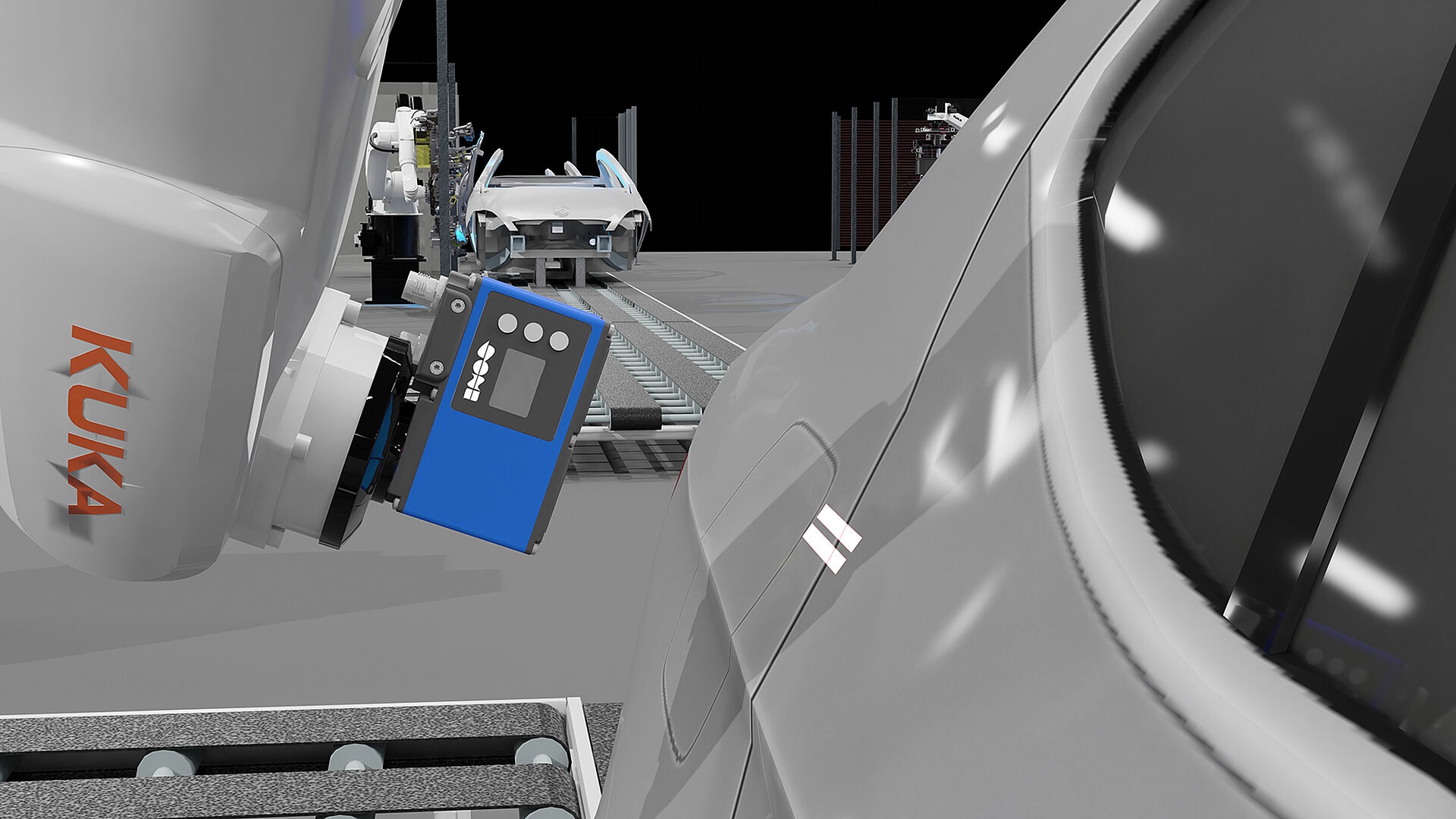

A robot-controlled 3D sensor inspects irregularities, the correct path, and the volume of the weld seam. During this process, the sensor optically scans the weld seam in all three directions in the room.

inos Automation offers

- a maximum resolution of up to 0.05 mm

- a sensor frequency in the range of 2-4 KHz

- a robot speed in the range of 10-200 mm/s

The scanned data is then compared to the CAD model of the inspection object to localize the defects found precisely and thus facilitate post-processing.

Which types of welds can be tested?

inos Automation's intelligent seam inspection can be applied to all joining technologies such as MIG/MAG welding, laser welding and soldering, friction stir welding and resistance welding.

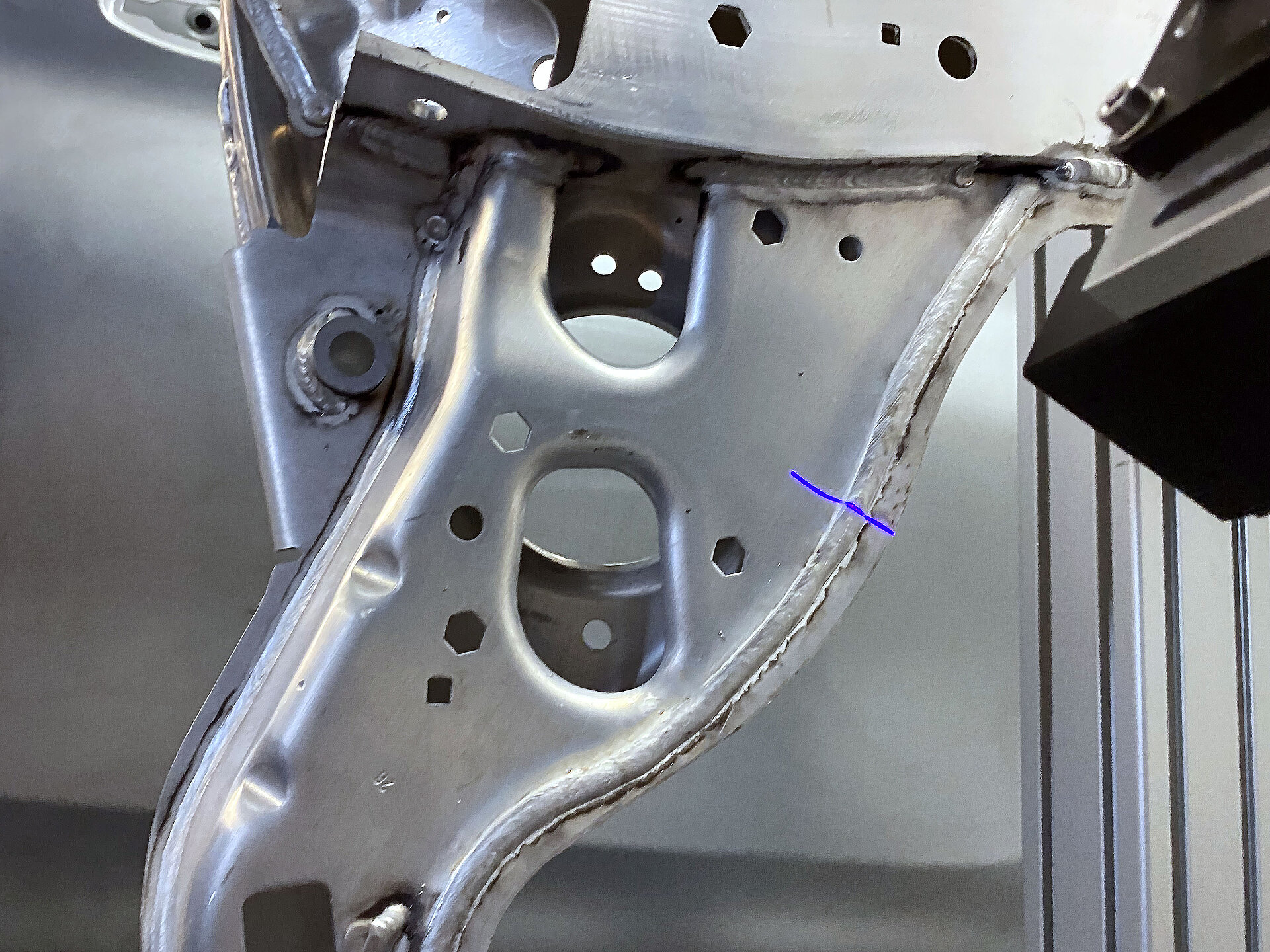

Which welding defects can be identified by the Weld Seam Inspection?

The 3D Weld Seam Inspection detects different defects, such as

- pores

- splashes

- edge offsets

- weld seam edges

- width

which cannot be seen with the naked eye.

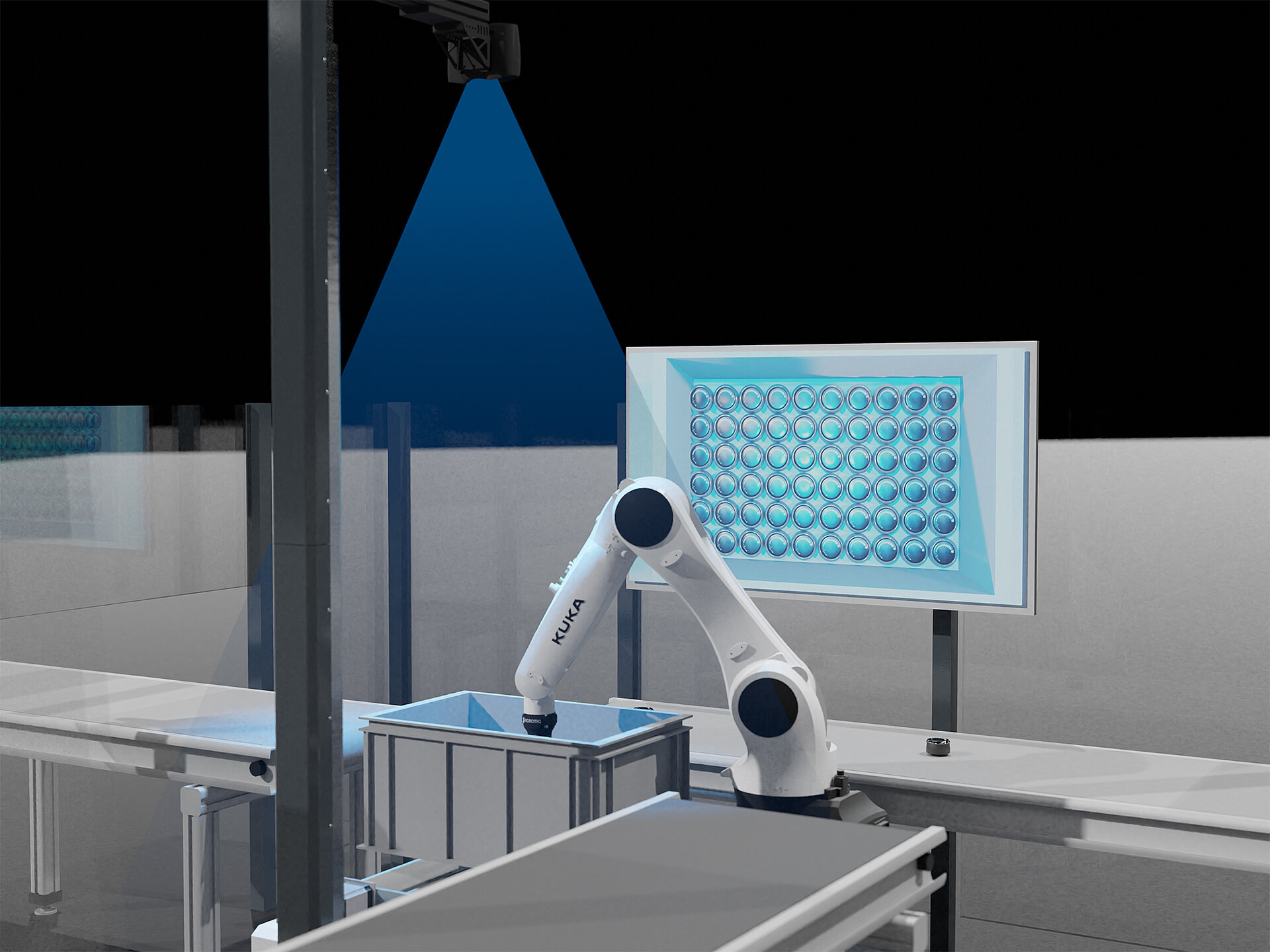

How does AI optimize the inspection of weld seams?

inos Automation optimizes the quality control of weld seams using machine learning and algorithms. The inos Automation algorithms analyze the 3D models of the component generated by the sensors to identify even the smallest irregularities in the weld seam.

The inos Automation software solution allows for a detailed inspection and assessment of the data. The most important KPIs and information are visualized, and reports are prepared via a web front end.

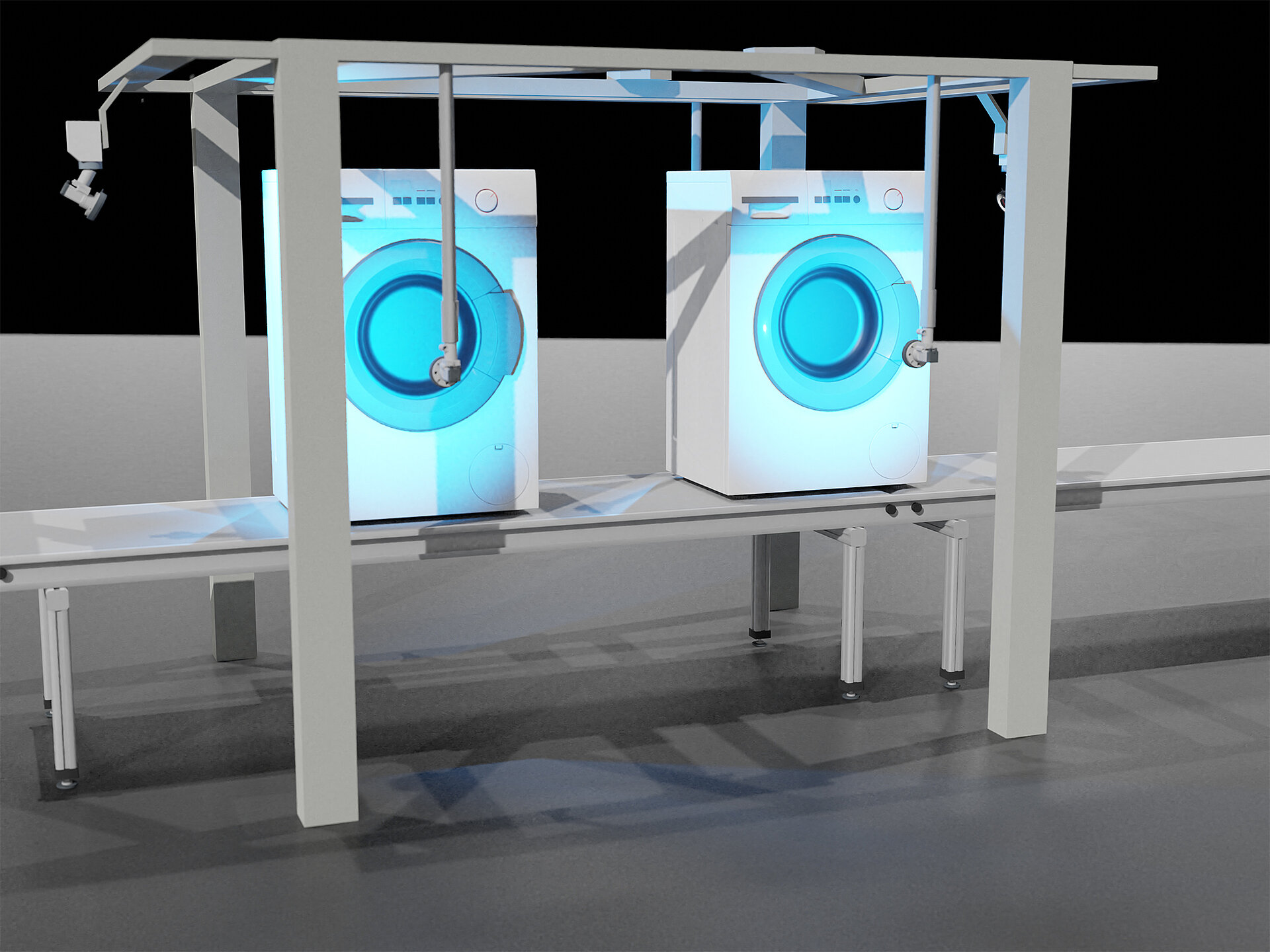

Turnkey solutions from a single source

Would you like to inspect your weld seams and need a solution from a single source? You came to the right place!

We have a wealth of experience in supporting our customers and know how different the requirements for quality control can be.

From software to hardware – we provide you with every component you need on a modular basis or from a single source. Always customized to your wishes. Our service team will continue to provide you with active support after installation.

We support you with vision technology and software solutions

GIVE VISION TO YOUR PROCESSES

Your Contact Person: Stephan Mengele

You want to check the quality of your weld seam and prepare your quality control for the future? We’re happy to help you!