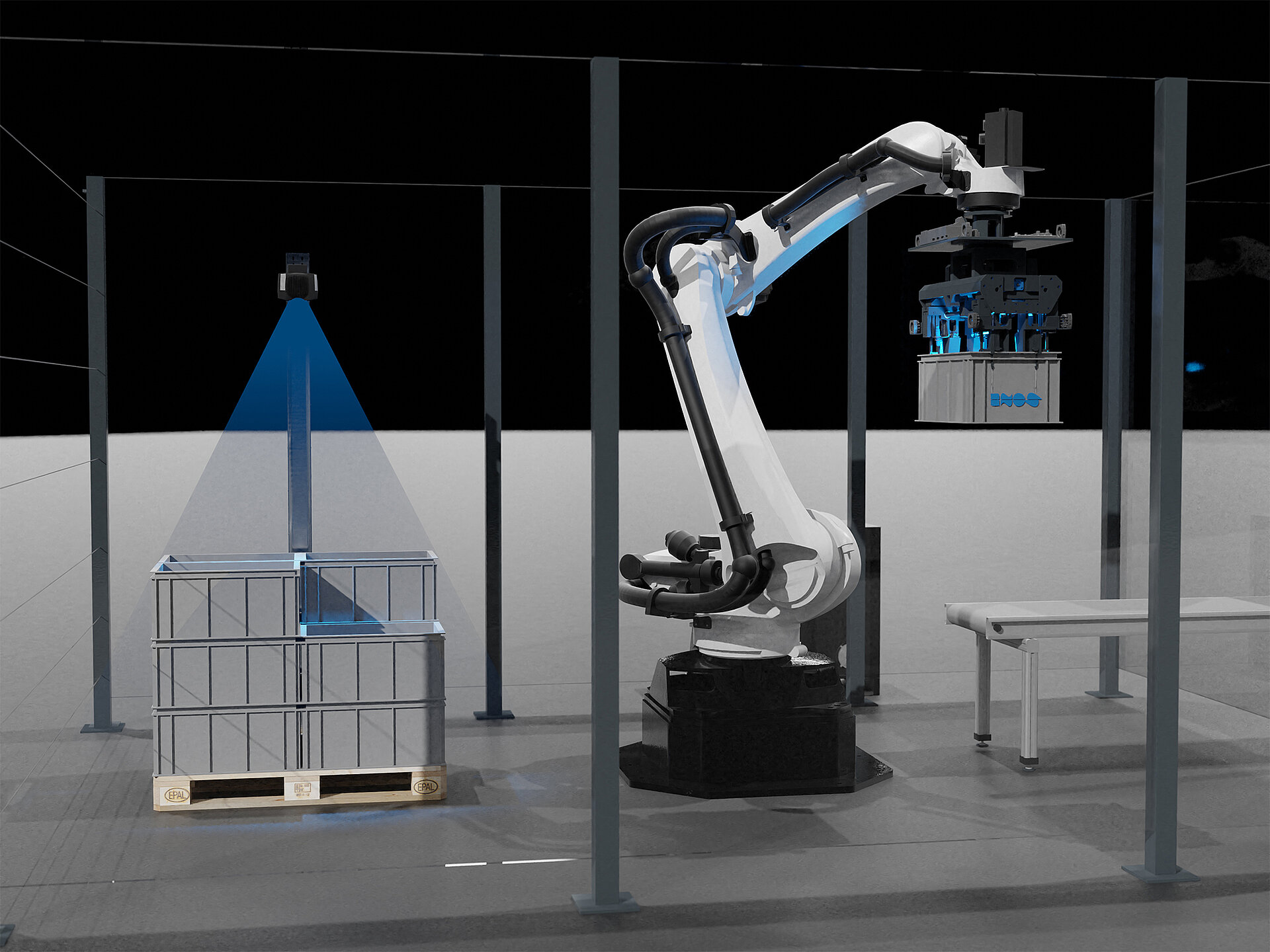

Palletizing systems for package handling

Palletizing processes with vision

Inefficient processes, damage to goods and accidents at work cost time and money and go hand in hand with high physical strain for employees. The key to success: efficient intralogistics.

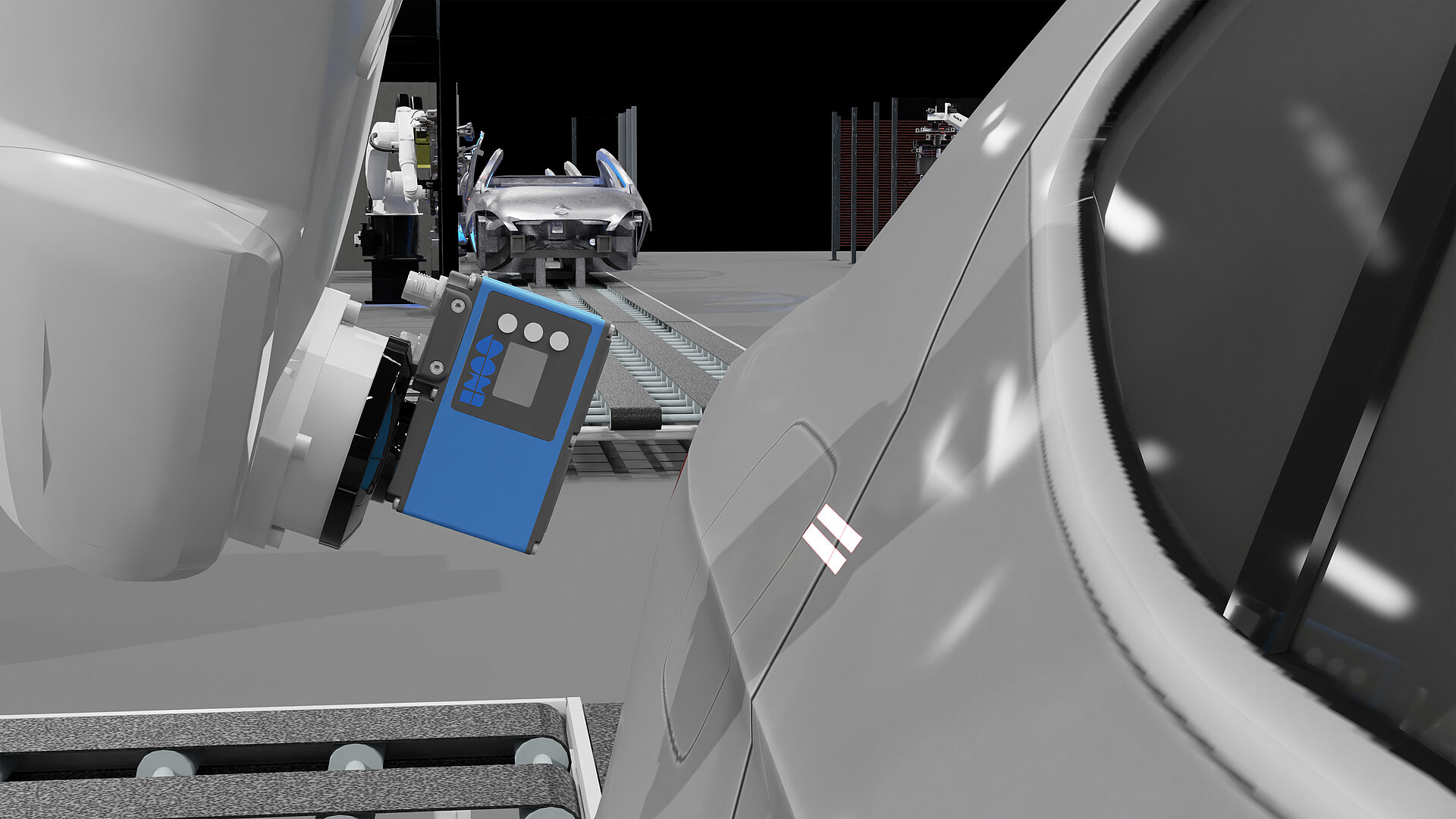

inos offers innovative solutions to standardize and automate logistics processes. The focus is always on robotics and image processing for tomorrow’s logistics. Machine vision provides foresight and teaches your robots to “see.” Pallets therefore do not have to be placed exactly, nor does information about the unit load on the pallet have to be passed on to the system. The innovative, durable Palletizing and Depalletizing systems from inos help to make logistics processes efficient and thus to reduce costs in the long term.

With automation expertise and passion, cycle time is reduced and your company’s safety and productivity are sustainably increased.

“Industry 4.0 presents companies with new challenges. At the same time, the intelligent networking of machines and processes offers opportunities and enormous potential. inos has recognized these opportunities. As one of the most innovative companies in the field of vision systems, we also handle other Industry 4.0 topics such as artificial intelligence, deep learning and machine learning. In this way, we can always offer our customers the latest technology for Industry 4.0.”

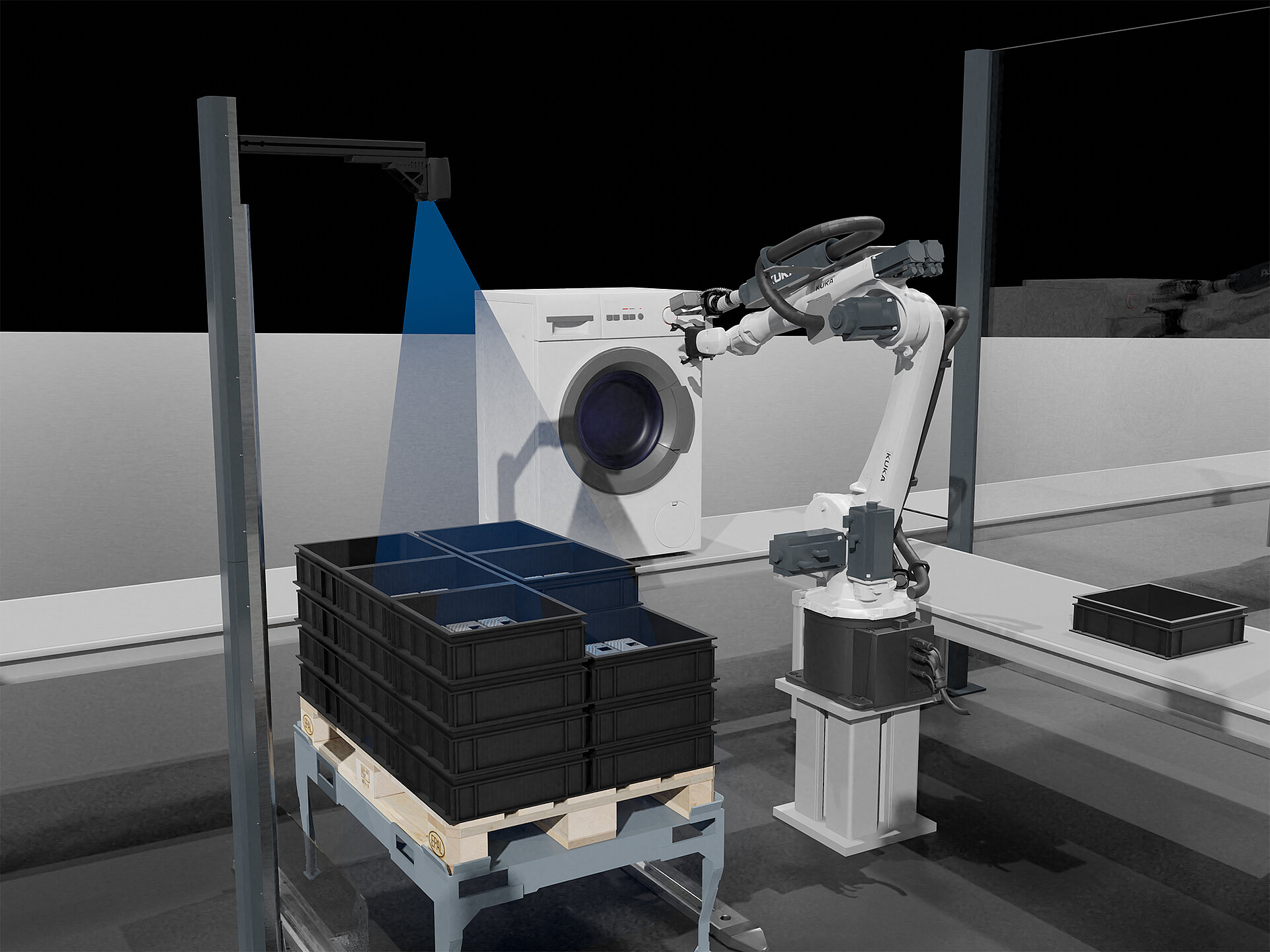

Depalletizing of small load carriers

Suitable for all industries

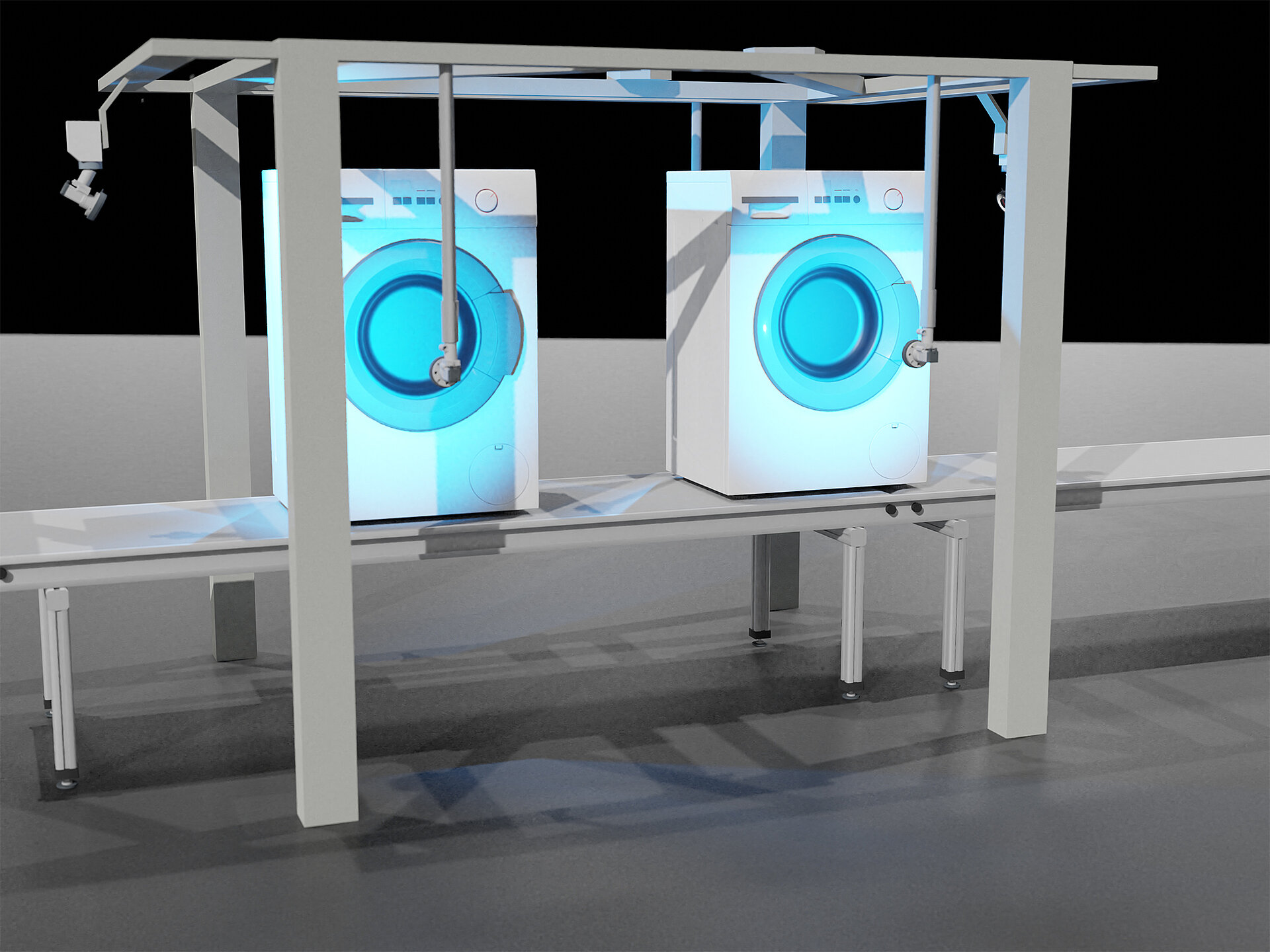

Small load carriers (SLC) have become an indispensable universal aid for internal and external transport, not only in the automotive industry but also in other sectors. SLCs are usually transported on mixed pallets to their destination, where they are often transferred to conveyor technology.

- Automated sensor-based Depalletizing offers maximum functionality and flexibility

- Integrated 3D sensor technology detects the position of containers on the pallet

- Robots depalletize the individual SLC with a cycle time of less than 12 seconds

- Employees avoid physical strain and can be deployed elsewhere at the same time

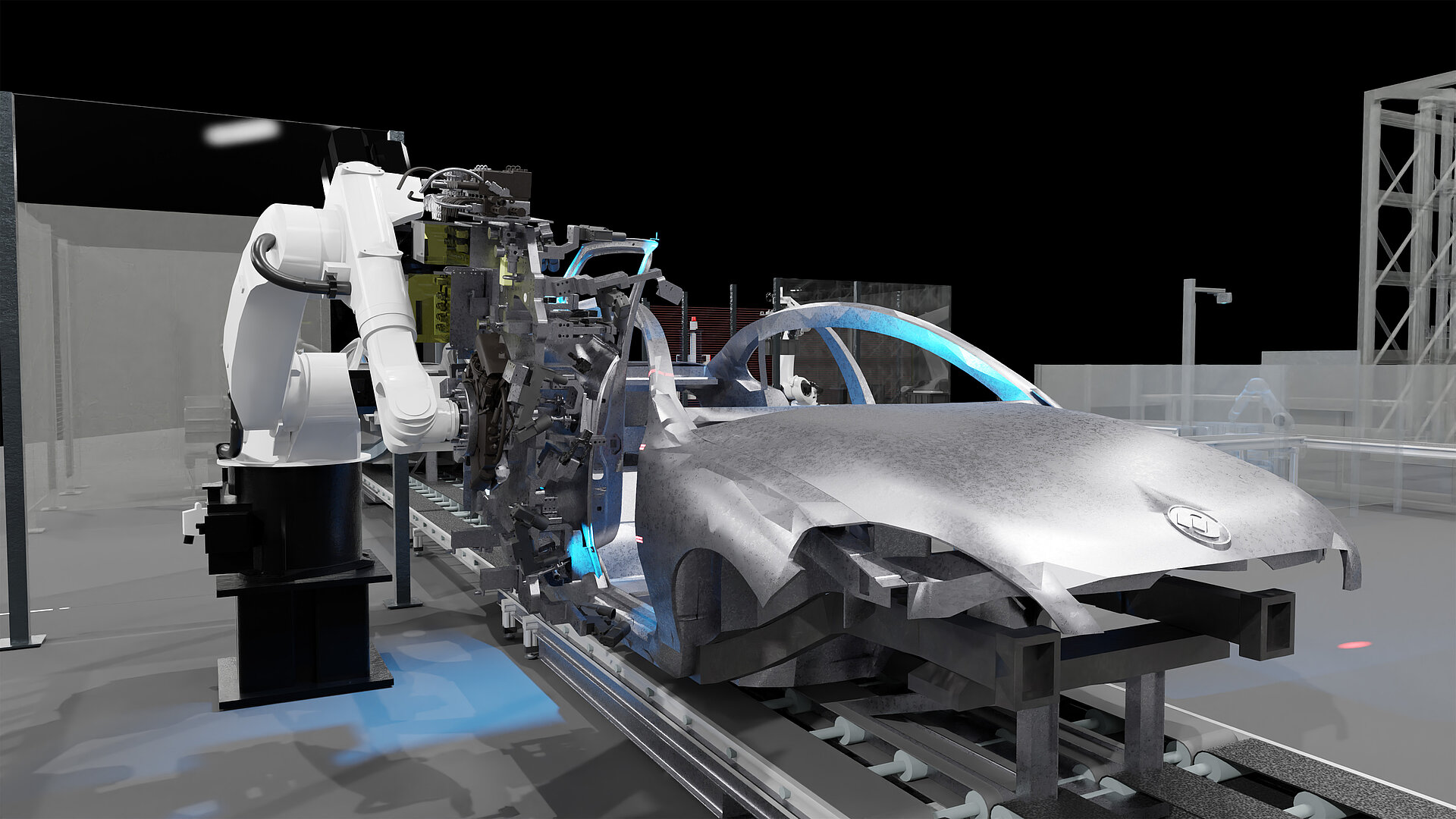

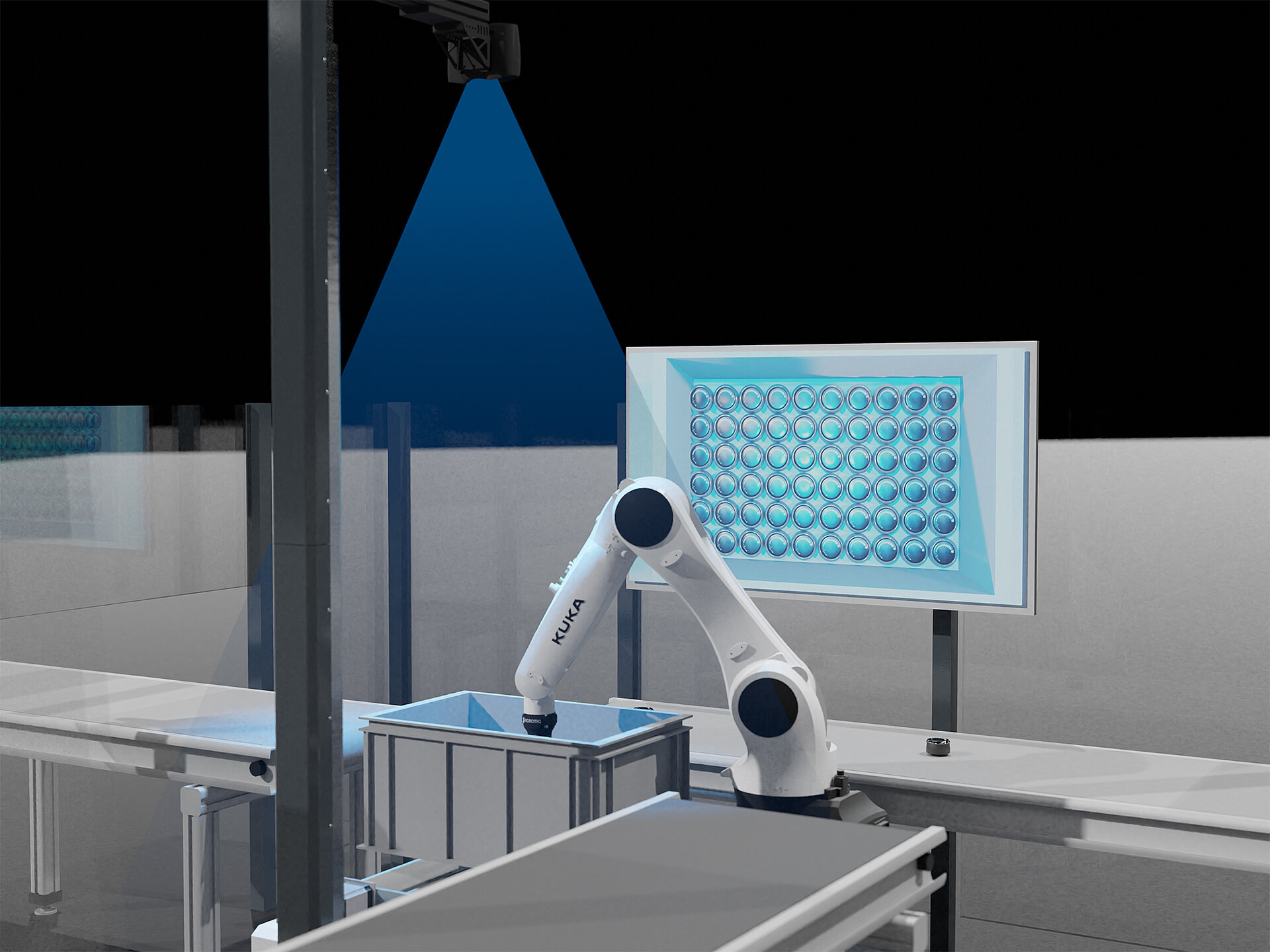

Palletizing of mixed pallets

In the logistics industry, Palletizing is one of the most basic processes. However, these processes are becoming increasingly complex due to the increase in the number of variants, the increased individualization of orders and the decrease in parts per packaging unit. Mixed pallets offer the advantage that objects can be stacked more efficiently. At the same time, the stability of the packages must be ensured.

- Automated sensor-based palletizing offers maximum functionality and flexibility

- Integrated 3D sensor technology scans both the pallet and the packages

- The sensor calculates the ideal palletizing strategy in real-time for maximum stability

- Robots palletize the individual piece goods

- Pallet can be loaded more efficiently and higher

- In the automated duo, another robot wraps the pallet at the same time

Complete solution from a single source

Do you want to automate, adapt or renew your logistics? Are you looking for a complete solution from a single source? Then you’ve come to the right place!

From software, such as the vision sensor, to hardware, such as robots and grippers, we can supply you with any component you need on a modular basis or from a single source – always tailored to your requirements.

Do you want to adapt your production to Industry 4.0 and integrate vision in your processes? Contact us for your personal consultation.

We live Service

Let’s talk about partnership

Keeping your material handling solution highly available – that’s what we work for passionately, on track with research and practice. It is important to us that your Palletizing systems run reliably and that you can flexibly adapt your processes at any time as your requirements change.

With inos, you enter into a trusting partnership with a reliable partner over the entire lifecycle of your solution. Our global network is ready. We think ahead for you, accompany you and offer service with added value and vision.

We support you with vision technology and software solutions

Give your processes vision

Your Contact Person: Jürgen Schenk-Deisenhofer

Do you want to palletize and depalletize with system and adapt your logistics to Industry 4.0? We’ll be happy to help you!