Always in view: Your products’ quality and dimensions

Turnkey solution for quality inspection

The core of every production and manufacturing process is high-quality workpieces – in the right dimensions. However, both external and internal factors can lead to process deviations and affect the dimensions of critical features. Skilled personnel must stop production, find the source of the problem, quarantine the affected products, and then either manually rework or reject them. This is neither efficient nor profitable for companies in any industry.

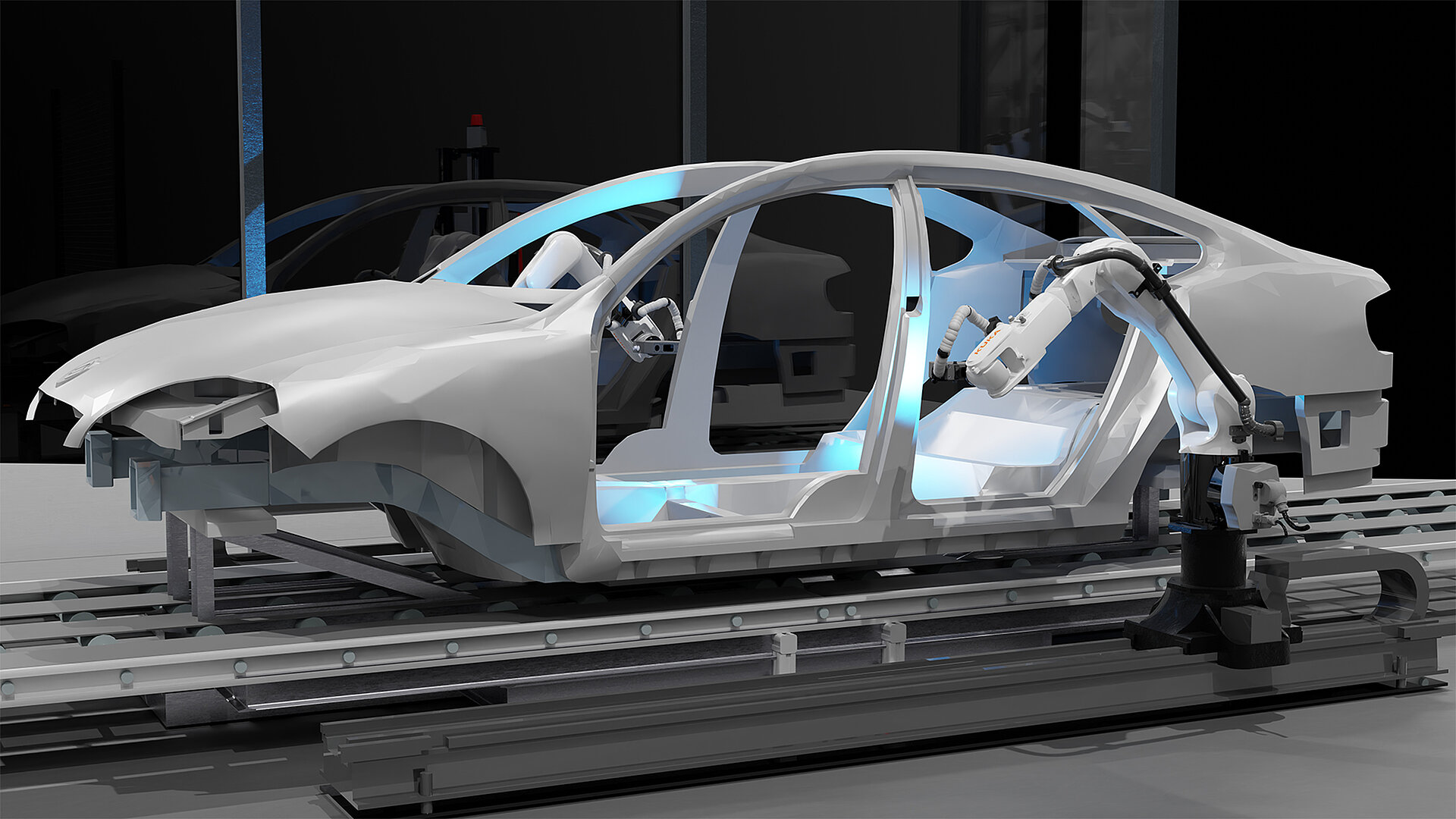

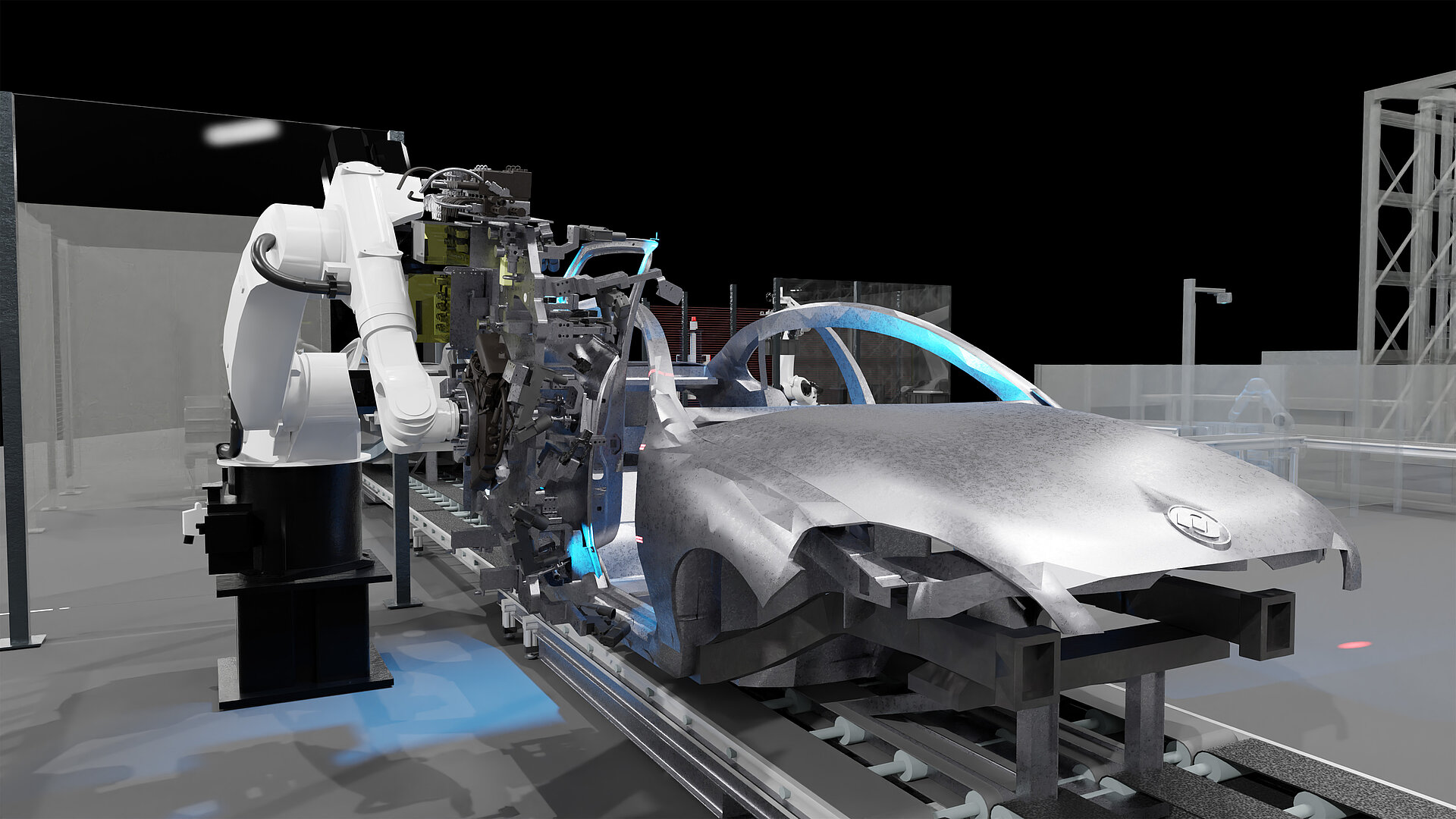

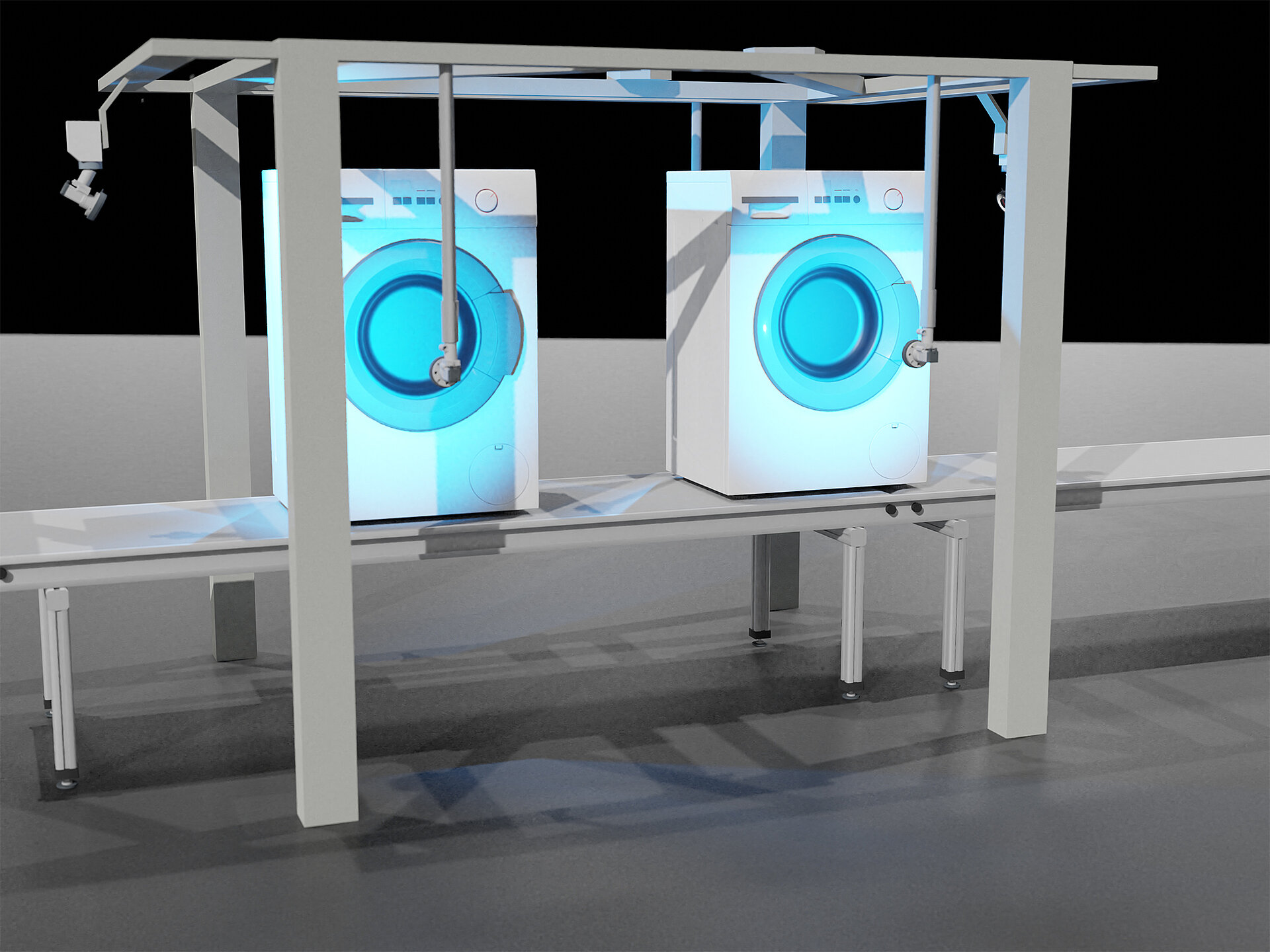

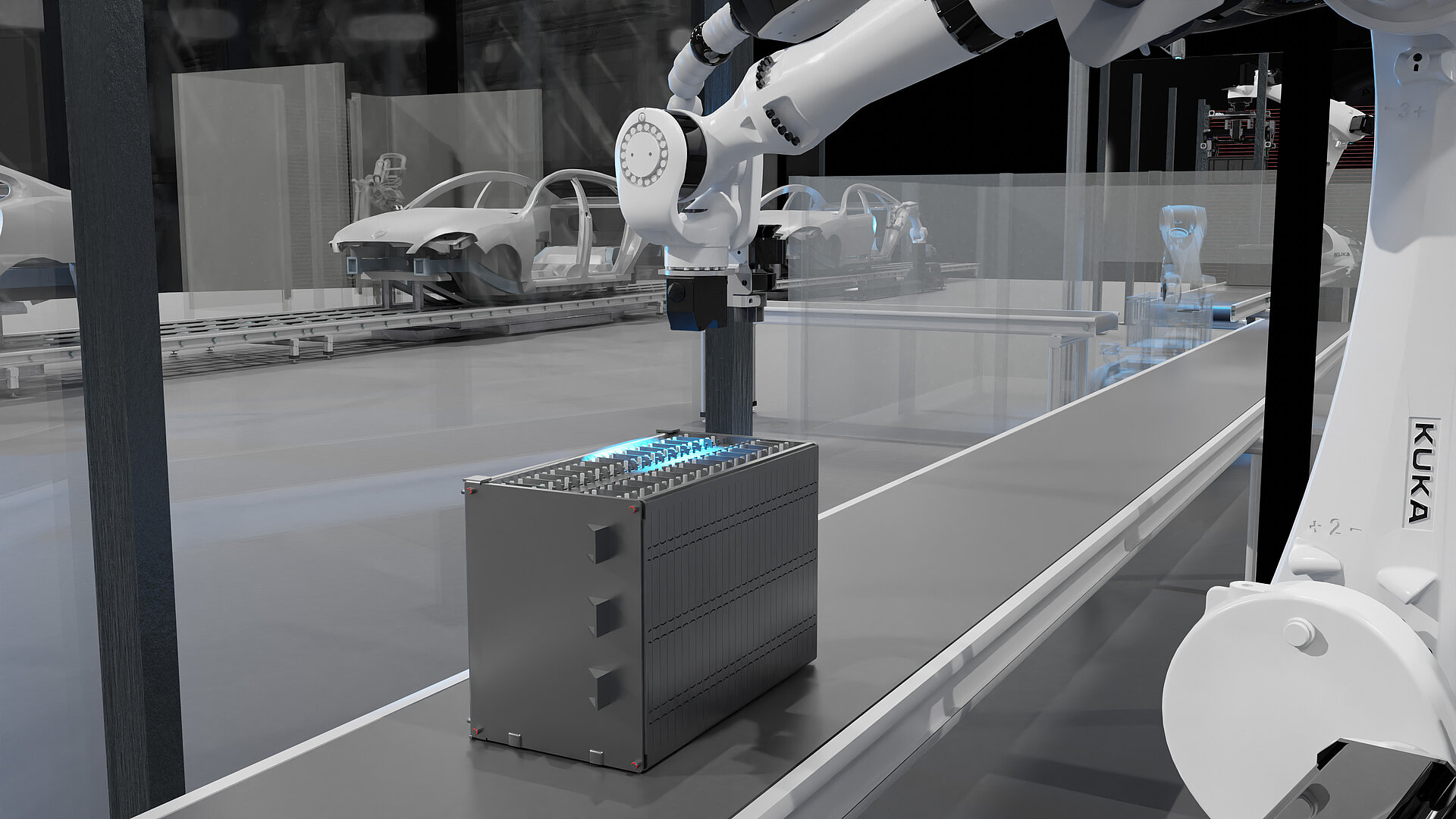

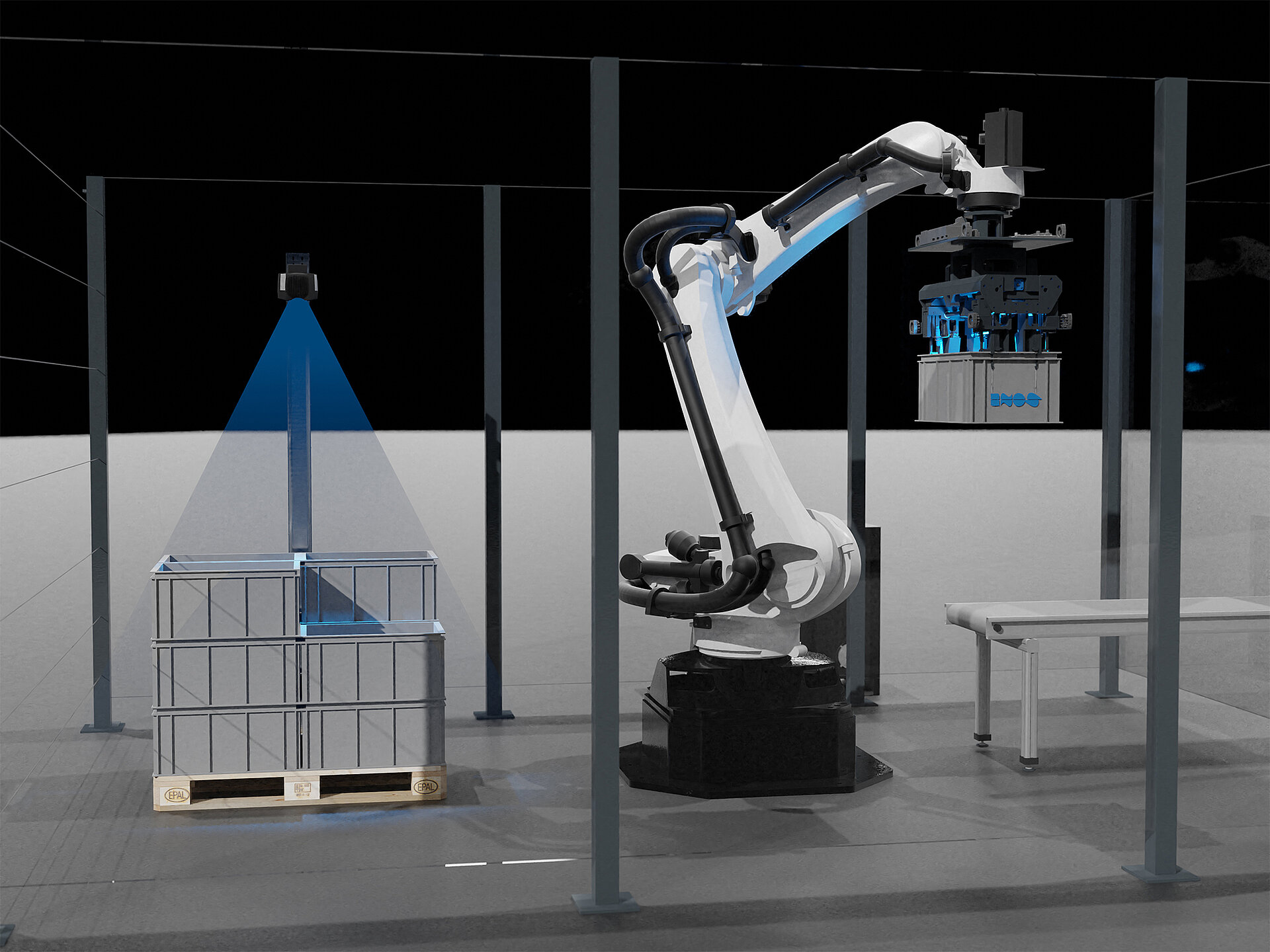

inos supports companies in mastering these tasks and makes inspection processes more efficient and economical with machine vision. As a turnkey solution for inspecting dimensions, inos’ 3D Inline Metrology significantly reduces the rework and reject rate for workpieces and component groups, as well as overall inspection time. The use of inos image processing systems in quality inspection leads to lasting increases in competitiveness and productivity and sustainably reduces the quality assurance department’s work.

Correlation-free inline measurement

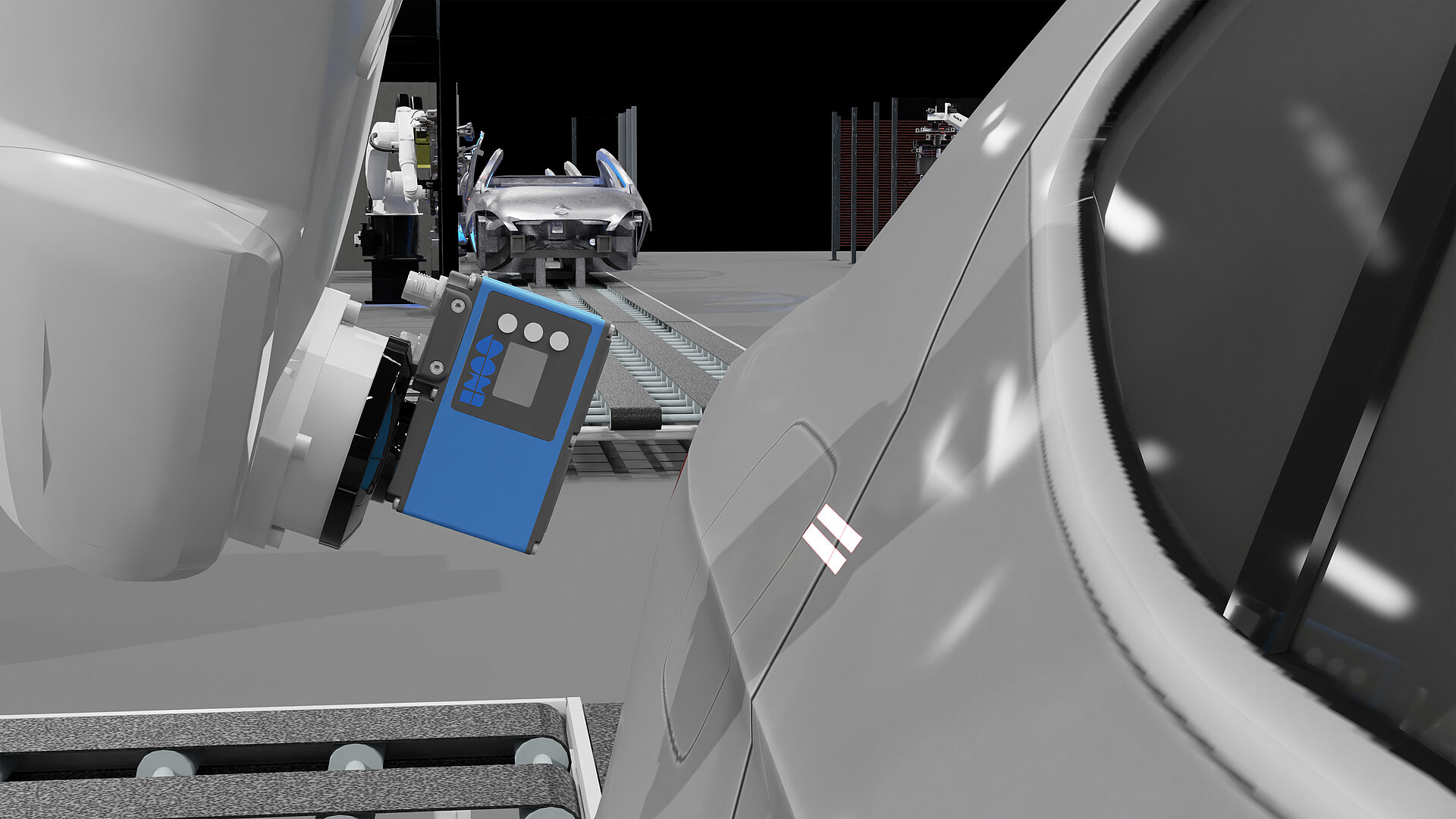

Correlation-free inline measurement technology enables the highest measurement quality and accuracy by eliminating the influence of robot-related inaccuracies.

Based on innovative technologies and algorithms, inos has developed a system for correlation-free measurement of complex features. Through continuous monitoring and analysis, potential quality deviations can be detected and corrected at an early stage. The system increases plant performance, shortens process lead times and minimizes costs for stationary measurement processes.

Our powerful reporting software – inos Analyzer – can track measurements and KPIs from multiple production lines and multiple devices in real-time. In addition, inos offers a customized reporting solution for companies. In addition to transparency, the software offers maximum flexibility as it is web-based and does not need to be installed on a PC.

Quality inspection

Intelligent automated measurements

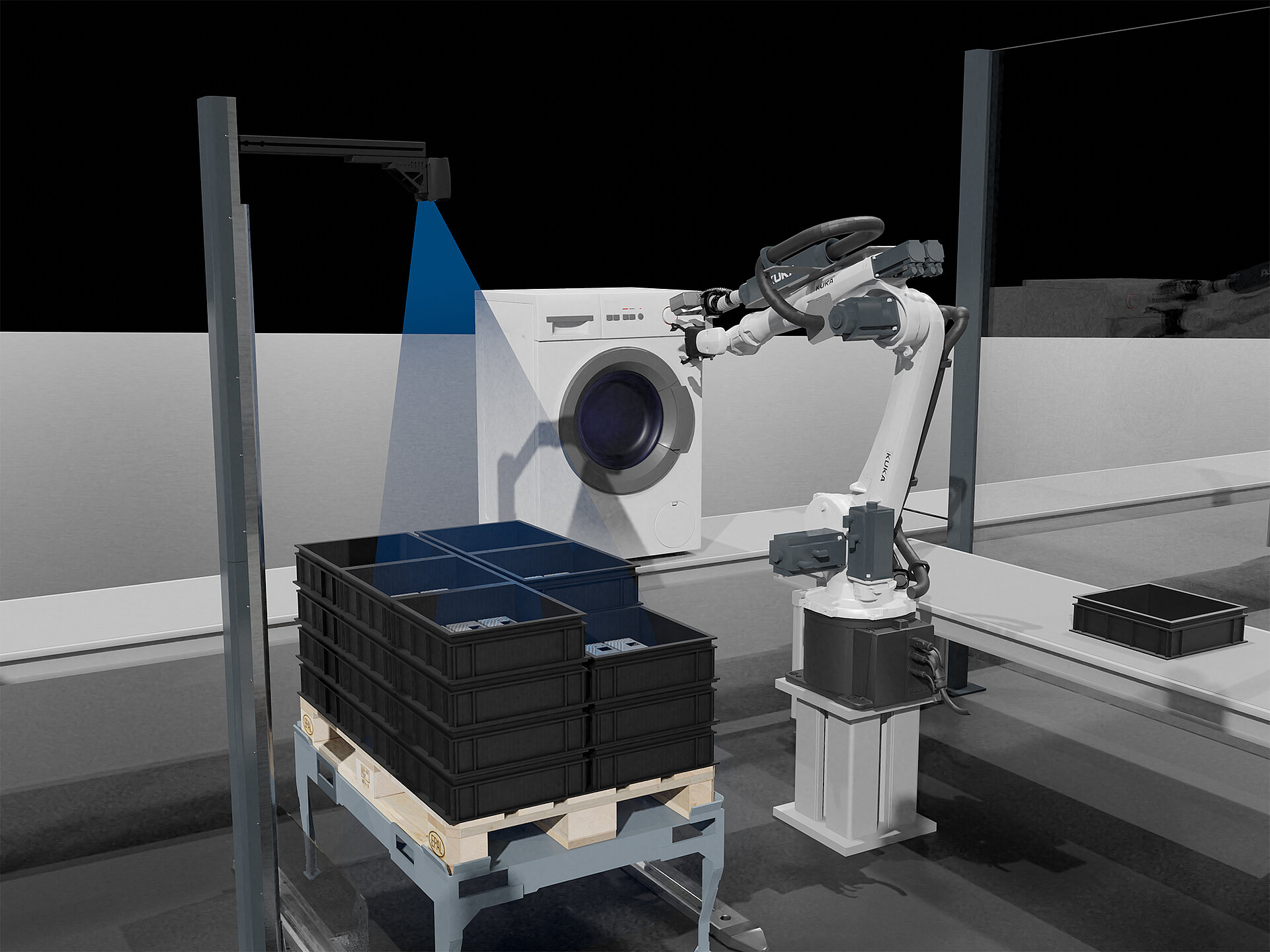

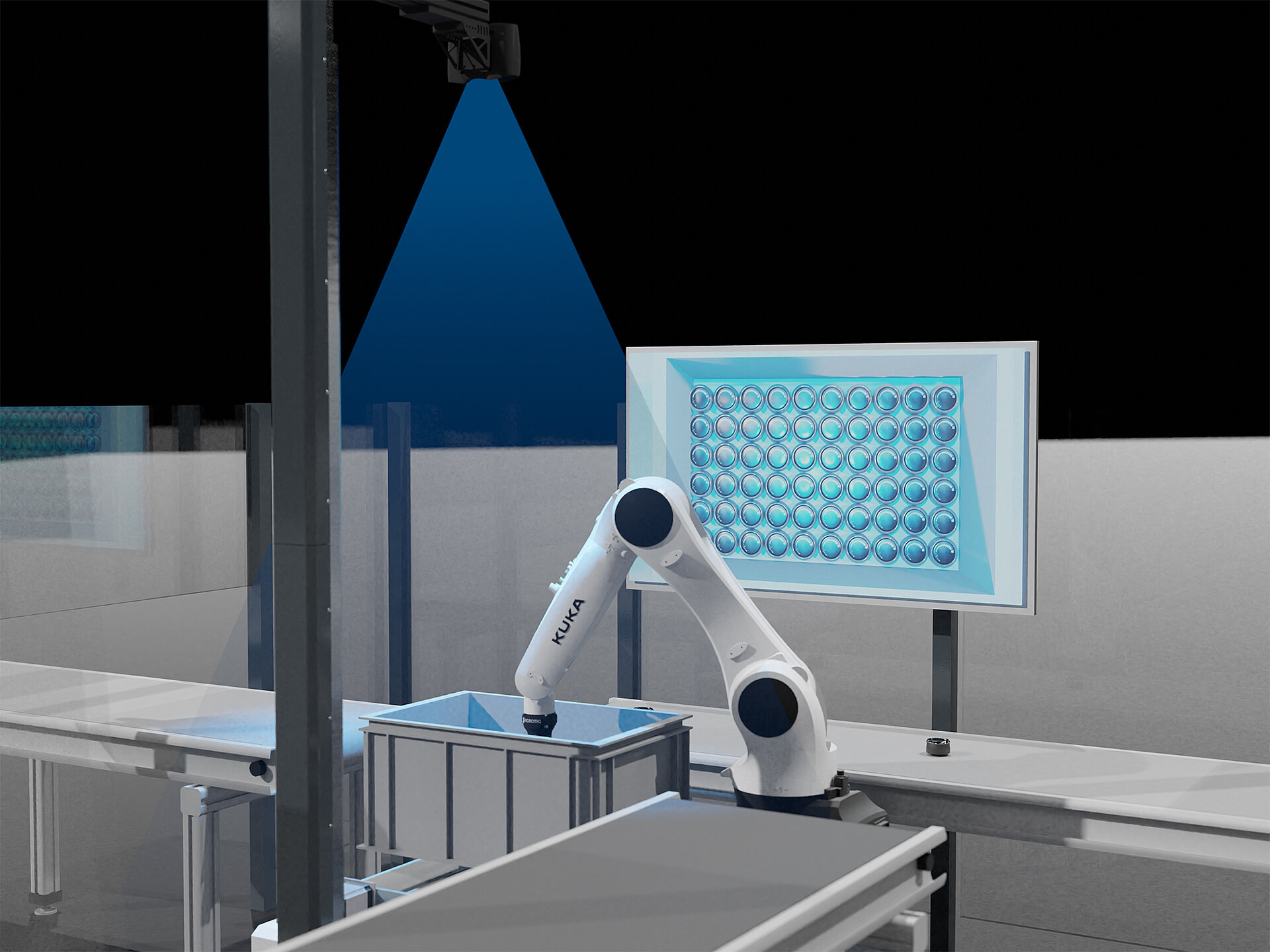

The demand for product quality is increasing. Rating portals, increasing globalization and individualization and changing user behavior put companies under pressure. With inos by your side, you can master these challenges. As a long-standing partner to our customers, we know how different their requirements for quality control can be. We are a full-service provider who supports customers with smart solutions to meet the demands of future markets, and we offer companies a modular system with numerous possibilities. At inos, you are the focus. Our quality inspection solutions cover any kind of control process. Get to know our extensive portfolio:

- 3D Inline Metrology for checking dimensions

- Assembly control for controlling features

- Gap and flush measurement for gap and flush control

Complete solution from one source

Do you want to automate, adapt or renew your quality control from scratch? Are you looking for a solution from a single source? Then you’ve come to the right place!

From software to hardware, we’ll give you every required component, whether modular or single-source – always tailored to your wishes.

Do you want to adapt your quality inspection to Industry 4.0 and integrate vision in your processes? Contact us for your consultation and discussions.

“With 3D Inline Metrology from inos, our customers are always one step ahead of the competition. Within a few seconds, customers have more than 100 measuring points. And due to our temperature compensation system, our inline measuring systems deliver consistent results around the clock – always intending to give our customers the highest possible transparency, freedom of action and quality.”

We live Service

Let’s talk about partnership

Keeping your solution available in production – that’s what we work passionately to achieve, on track with research and practice. It is important to us that your quality control runs reliably and that you can flexibly adapt your processes at any time as your requirements change.

With inos you enter into a trusting partnership throughout the lifecycle of your solution. Our global network is ready. We think ahead for you, accompany you and offer service with added value and vision.

We support you with vision technology and software solutions

Give your processes vision

Your Contact Person: Thomas Klaiber

Do you want to constantly improve the quality of your products and adapt your quality assurance to Industry 4.0? We’re happy to help you!